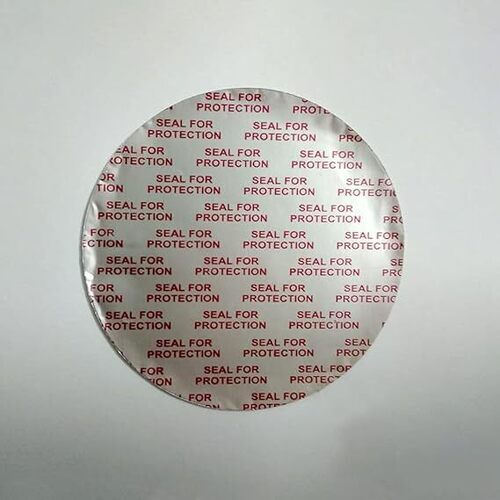

Sealing Wads

Price 0.30 INR/ Piece

Sealing Wads Specification

- Product Type

- Sealing Wads

- Material

- Aluminium Foil and Polyethylene

- Adhesive

- Pressure Sensitive or Heat Induction

- Adhesive Side

- Single Side

- Tensile Strength

- High

- Width

- Customized as per requirement

- Length

- Customized as per requirement

- Thickness

- 0.5 mm to 1.2 mm

- Size

- Customized sizes available

- Color

- White / Silver

- Why Do You Need This ?

- To provide leak-proof and tamper-evident sealing for containers

About Sealing Wads

Sealing wads are typically used in various applications to create a tight seal and prevent leaks or contamination. They can be found in different industries, including firearms, packaging, and even in some manufacturing processes.Packaging: In packaging, sealing wads (also known as liners or seals) are used to create a hermetic seal on containers. This helps to keep the contents fresh and prevents leakage. These can be made of various materials like plastic, aluminum, or paper.

Versatile Sealing Solutions

Our sealing wads are ideal for a spectrum of industries-pharmaceutical, food, cosmetics, and chemicals. Manufactured using high-grade aluminium foil and polyethylene, these wads come in round, pre-cut, or custom shapes. Whether your containers are PET, HDPE, PP, or glass, our wads ensure reliable, leak-proof seals with tamper evidence. Flexible in both size and thickness, they provide excellent tensile strength and heat resistance.

Efficient and Secure Sealing Process

Sealing wads offer two sealing methods: induction and pressure-sensitive. Induction sealing involves a non-contact process using electromagnetic induction to melt the adhesive, bonding the wad to the bottle. Pressure-sensitive wads adhere with moderate pressure. Both methods create protective, secure seals, guarding contents from contamination while preserving freshness and integrity.

Custom Printing and Packaging Options

Enhance your brand with our printing services-logos and precise instructions can be added to every sealing wad. All wads are packed according to your preference in boxes or polybags, ensuring product integrity during storage and transportation. Each order can be tailored for specific dimensions, quantity, and visual branding requirements.

FAQ's of Sealing Wads:

Q: How do induction and pressure-sensitive sealing wads work?

A: Induction sealing wads use electromagnetic induction to heat the aluminium foil, which bonds the wad to the container's rim to create an airtight seal. Pressure-sensitive wads rely on a special adhesive that sticks securely to the bottle when moderate pressure is applied, requiring no heat. Both methods provide tamper-evident and leak-proof closure for your containers.Q: What types of bottles and containers are compatible with these sealing wads?

A: Our sealing wads are compatible with a wide range of containers, including those made from PET, HDPE, PP, and glass. Their customizable sizes and shapes ensure a perfect fit for bottles and jars of varying dimensions across several industries.Q: In which industries can these sealing wads be used?

A: Sealing wads are ideal for pharmaceutical, food, cosmetics, and chemical packaging applications. They provide hygiene, prevent leaks, and ensure product integrity for substances requiring safe storage and tamper evidence.Q: What are the customization options for these sealing wads?

A: You can customize the shape (round, pre-cut, or bespoke), size (length and width), thickness (0.5 mm to 1.2 mm), and printing (logo or instruction). This ensures every wad meets your specific packaging and branding requirements.Q: What are the benefits of using sealing wads in packaging?

A: Sealing wads offer important benefits such as leak-proof sealing, tamper evidence, extended shelf life, and protection against contamination. Custom printing adds a layer of brand recognition and compliance instruction for consumers.Q: How should sealing wads be stored and what is their shelf life?

A: Store the sealing wads in a cool, dry place to maintain their adhesive and material quality. When properly stored, they have a shelf life of up to 24 months, ensuring long-term reliability for your packaging needs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Induction Sealing Wads Category

Induction Heat Sealing Wads

Price 0.30 INR / Piece

Minimum Order Quantity : 500 Pieces

Why Do You Need This ? : Other, Ensures leakproof and tamperevident packaging for bottles and containers

Material : Other, Aluminum Foil + Polymer Layer

Adhesive : Other, Heat Activated

Size : Custom sizes available

Round Induction Sealing Wad

Price 150 INR / Piece

Minimum Order Quantity : 4000 Pieces

Why Do You Need This ? : For Business Use

Material : Other, Aluminum

Adhesive : Acrylic

Size : Different Sizes Available

0.6mm Induction Sealing Wad

Price 150 INR / Piece

Minimum Order Quantity : 4000 Pieces

Why Do You Need This ? : For Business Use

Material : Other, Aluminum

Adhesive : Acrylic

Send Inquiry

Send Inquiry