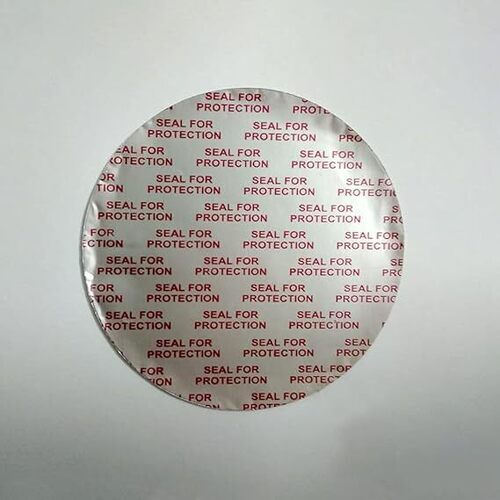

Induction Heat Sealing Wads

Price 0.30 INR/ Piece

MOQ : 500 Pieces

Induction Heat Sealing Wads Specification

- Product Type

- Induction Heat Sealing Wads

- Material

- Aluminum Foil + Polymer Layer

- Adhesive

- Heat Activated

- Adhesive Side

- One side adhesive for sealing

- Tensile Strength

- Highsuitable for secure sealing

- Width

- Customizable

- Length

- Customizable as per container size

- Thickness

- Typically 0.3 mm 1 mm

- Size

- Custom sizes available

- Color

- White with aluminum finish

- Why Do You Need This ?

- Ensures leak-proof and tamper-evident packaging for bottles and containers

About Induction Heat Sealing Wads

Order our top-rated Induction Heat Sealing Wads, meticulously crafted for resplendent performance in sealing PET, HDPE, PP, and glass containers. These scarce, polished wads feature an exquisite aluminum foil and polymer layer, ensuring a strong, air-tight, and leak-proof seal. With robust moisture and temperature resistance up to 180C, they secure valuable contents in pharmaceutical, food & beverage, chemical, cosmetic, and agro-industry applications. Choose bulk or customized packs tailored to your needs. Custom printing and branding services add a sophisticated touch to every seal, delivering unrivaled packaging integrity.

Versatile and Reliable Sealing Solution

Induction Heat Sealing Wads are ideal for pharmaceutical, food & beverage, chemical, cosmetic, and agro-industry applications. Made from aluminum foil with a heat-activated polymer layer, these wads provide strong tensile strength and excellent moisture resistance. Compatible with both conduction and induction sealers, they ensure resplendent, leak-proof, and tamper-evident packaging. Customizable in size, width, and thickness, these exquisite sealing wads deliver flawless seal integrity for a diverse range of containers.

Sample Policy, Logistics & Payment Details

Our sample policy allows buyers to request wads samples at a competitive asking price before bulk orders. Logistics are streamlined via the nearest FOB port in India, ensuring prompt and seamless handover of shipments. Payment terms are flexible, offering secure transaction options for manufacturers and suppliers. Whether you require bulk or customized packs, we ensure reliable handover and transparency throughout the procurement process for maximum satisfaction.

Versatile and Reliable Sealing Solution

Induction Heat Sealing Wads are ideal for pharmaceutical, food & beverage, chemical, cosmetic, and agro-industry applications. Made from aluminum foil with a heat-activated polymer layer, these wads provide strong tensile strength and excellent moisture resistance. Compatible with both conduction and induction sealers, they ensure resplendent, leak-proof, and tamper-evident packaging. Customizable in size, width, and thickness, these exquisite sealing wads deliver flawless seal integrity for a diverse range of containers.

Sample Policy, Logistics & Payment Details

Our sample policy allows buyers to request wads samples at a competitive asking price before bulk orders. Logistics are streamlined via the nearest FOB port in India, ensuring prompt and seamless handover of shipments. Payment terms are flexible, offering secure transaction options for manufacturers and suppliers. Whether you require bulk or customized packs, we ensure reliable handover and transparency throughout the procurement process for maximum satisfaction.

FAQs of Induction Heat Sealing Wads:

Q: How do Induction Heat Sealing Wads ensure packaging integrity?

A: These wads utilize a heat-activated adhesive and a polished aluminum foil layer to create a strong, air-tight, and leak-proof seal, safeguarding containers from leaks and tampering.Q: What container materials are compatible with these sealing wads?

A: They are compatible with PET, HDPE, PP, and glass containers, making them suitable for a wide array of packaging needs across various industries.Q: When should I use induction heat sealing wads in my packaging process?

A: You should employ induction heat sealing wads whenever an air-tight, tamper-evident, and moisture-resistant seal is required for bottles or containers in pharmaceutical, food & beverage, chemical, cosmetic, or agro-industries.Q: Where can I get custom sizes or shapes for the wads?

A: Custom sizes, widths, shapes (including round and others on request), and thicknesses are available by specification and order, directly from the manufacturer or supplier in India.Q: What is the process for ordering samples and how is logistics managed?

A: Samples can be requested at an asking price prior to bulk ordering, and logistics are handled through the nearest FOB port with transparent handover from our logistics team.Q: How does custom printing or branding benefit my business?

A: Custom printing allows you to feature branding on the wads, enhancing product presentation, reinforcing brand identity, and supporting traceability in the marketplace.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Induction Sealing Wads Category

Sealing Wads

Price 0.30 INR / Piece

Minimum Order Quantity : 500 Pieces

Why Do You Need This ? : Other, To provide leakproof and tamperevident sealing for containers

Adhesive : Other, Pressure Sensitive or Heat Induction

Material : Other, Aluminium Foil and Polyethylene

Size : Customized sizes available

Round Induction Sealing Wad

Price 150 INR / Piece

Minimum Order Quantity : 4000 Pieces

Why Do You Need This ? : For Business Use

Adhesive : Acrylic

Material : Other, Aluminum

Size : Different Sizes Available

0.6mm Induction Sealing Wad

Price 150 INR / Piece

Minimum Order Quantity : 4000 Pieces

Why Do You Need This ? : For Business Use

Adhesive : Acrylic

Material : Other, Aluminum

Send Inquiry

Send Inquiry